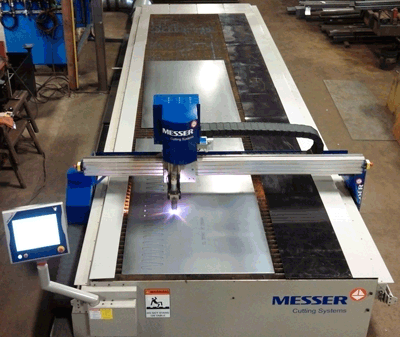

Berlon Acquires Messer Plasma Cutter

New System Streamlines Skid Steer Attachment Production

July 30, 2013

-- Berlon Industries of Hustisford, Wis., has entered a new era in manufacturing high quality buckets and attachments for skid steers and compact tractors by acquiring a high-tech metal cutting machine that relies on plasma-cutting technology.

The switch to plasma cutting is giving the 63-year-old company a higher rate of production, a cleaner facility and more precisely cut products that are already known for strength and durability.

Mike Ebben, president of Berlon Industries, said that the Messer EdgeMax HPR 260HD plasma cutter — installed at the company’s fabrication plant in nearby Juneau, Wis., has already significantly improved operations of the fabrication process and is part of the company’s overall drive to take the business to the next level.

"We want to create a world-class working environment," said Ebben. "We have great great products built by great people, but the work flow was always slowed down at our former metal cutting station. This new plasma work center is giving those people a world-class tool and letting them move products through the work flow much more efficiently."

In the past, Berlon’s primary fabricating plant in Juneau experienced bottlenecks created by the slower, weaker cutting system it used then, and thicker metals had to be shipped to another firm for fabrication.

"Just about everything goes through that work center," said Ebben about the plasma cutting system in the Juneau plant, calling it, "the heart of our manufacturing operation."

The cutting system, harnesses the cutting power of superheated gas. This gas is so hot that the molecules become ionized into plasma. This plasma is capable of smoothly and accurately cutting through mild steel up to 1.5 inches thick as well as stainless steel and aluminum up to an inch thick. The EdgeMax can cut up to 1,200 inches of material per minute with a laser-pointer-guided, touch-screen control system.

The new system also is creating a dramatically cleaner plant by virtually eliminating dross, the little bits molten metal debris that spew from metal as it is being cut, a messy and chronic problem with Berlon’s old cutting system.

The little amount of dross that is created by the EdgeMax is sucked into a vent beneath the machine and into a down-draft air filtration system.

The plasma cutter was acquired from Menomonee Falls, Wis.-based Messer Cutting Systems, a subsidiary of Messer Cutting Systems GmbH of Germany.

The purchase was the largest single capital investment in Berlon’s history. Based on the increased productivity from the plasma cutter, the company anticipates it will "pay for itself" in three years.

Berlon recently went through a complete company rebranding. It's new "Berlon Strong" logo represents the company's commitment to strength in engineering and design, manufacturing quality, business operations, personnel, support for dealers, customer service and community support.

As part of the rebranding process, Berlon has launched a new website that more fully represents its market position and the buckets and attachments it manufactures and sells. The site is at www.berlon.com.

***

Berlon designs and manufactures highly durable buckets and attachments for skid steers, tractor loaders, compact utility tractors, wheel loaders and telehandlers under the "Berlon Strong" approach. The company is known for offering premium products without a premium price tag, and for its extreme reliability in delivery commitments to its dealers. Berlon traces its roots to 1943 and, through a recent acquisition, remains privately held. Berlon has manufacturing and assembly plants in Hustisford and Juneau, Wisconsin, just northwest of Milwaukee. The company is on the web at www.berlon.com.